(616) 844-9220

EPS INDUSTRIES

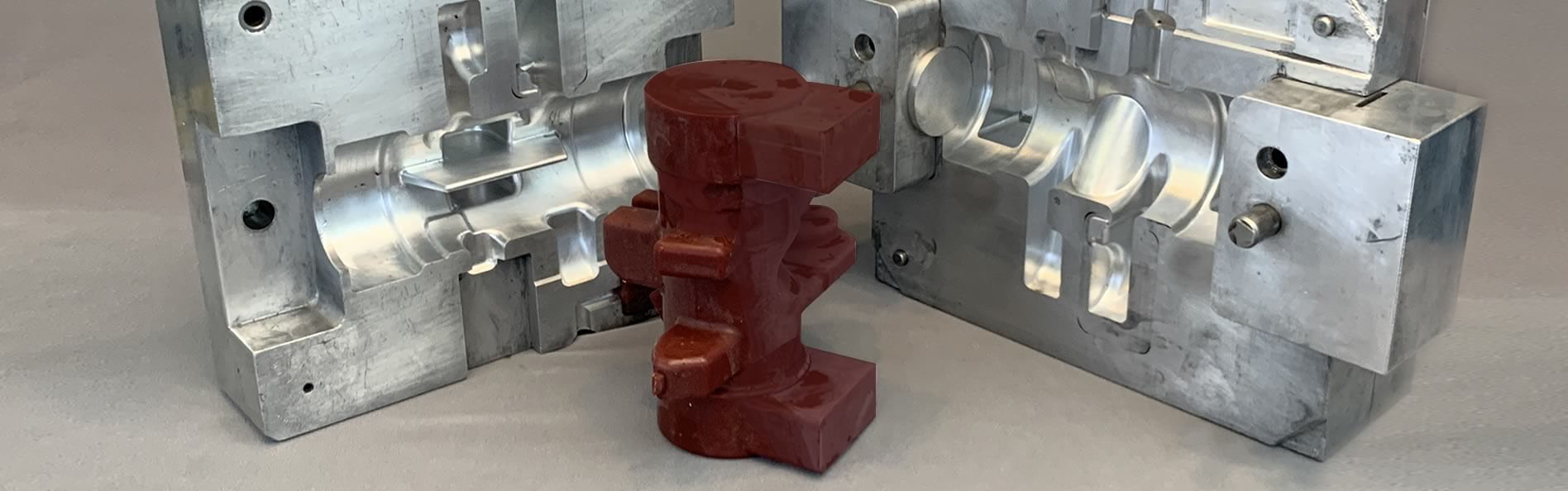

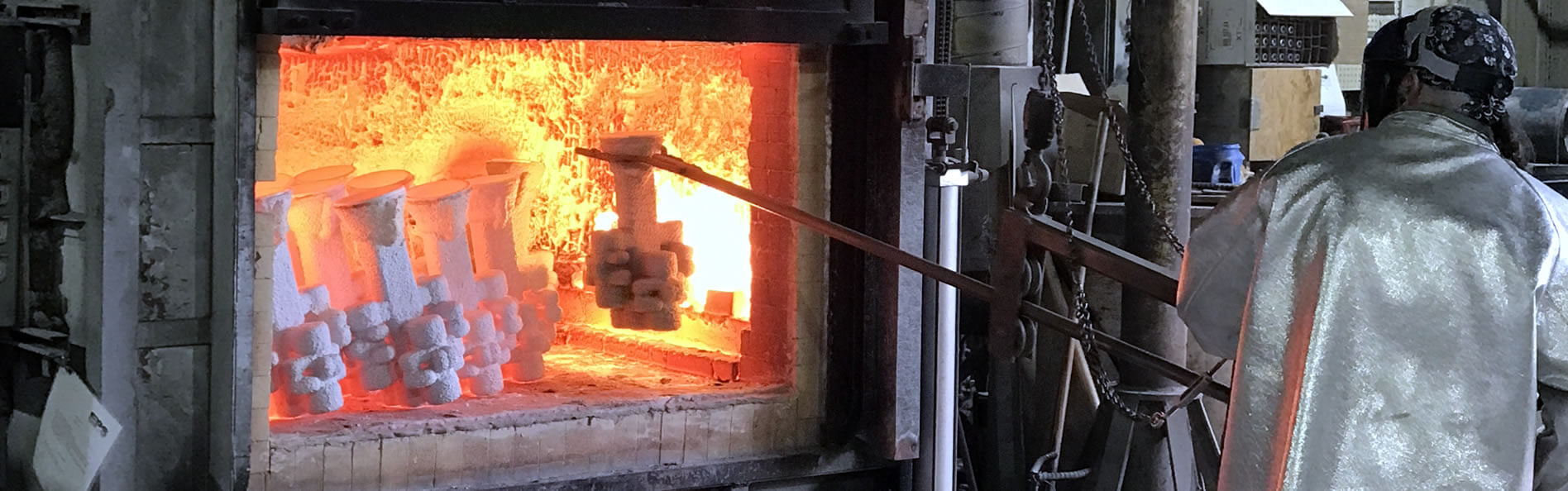

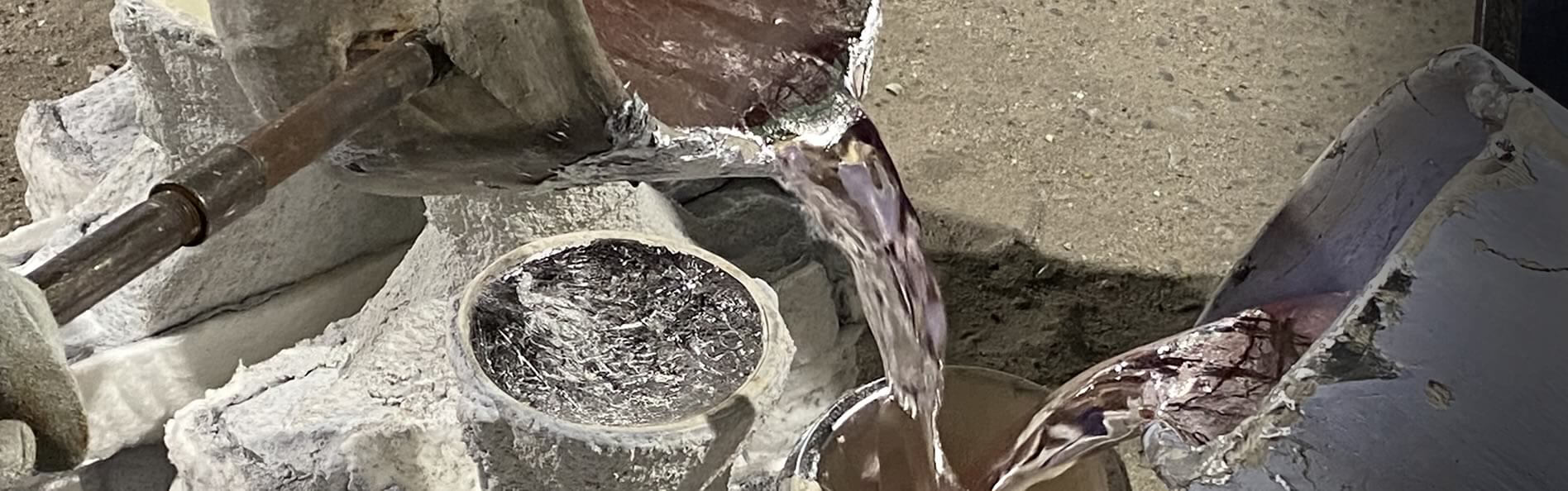

Lost Wax Process Investment Casting

EPS Industries - Your Experts in Investment Casting

EPS has been perfecting and continuously improving the art of investment casting since 2000. Our over 20 years of service manufacturing parts for the medical, transportation, military, steam component, pump and valve industries give us the base of expertise to provide you with the quality parts you need.

Why Lost Wax Process Casting?

Lost wax process investment casting is the closest you can get to a net shape manufacturing process. Using the lost wax method, EPS investment castings produce parts so close in tolerance that, in many cases, no further machining or finishing is necessary. Once the initial tooling is perfected, every subsequent casting is an identical copy of the original. You save time and money. Your customer gets a better product. Here’s how:

Gain Design & Materials Flexibility

Investment casting affords more freedom of design and access to a wider range of alloys than shell or sand castings offer. EPS routinely casts more than 120 ferrous and nonferrous metals.

Eliminate Tooling Set-up

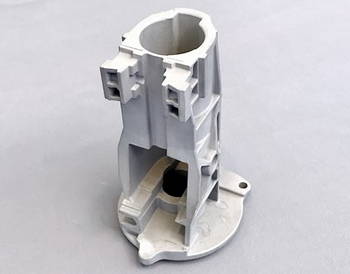

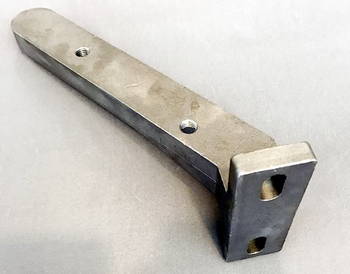

By offering near-net-shape configuration, fixturing costs are substantially reduced or eliminated altogether.

Reduce Production Costs

Precise dimensional tolerance of the lost wax process often eliminates machining on some surfaces, thus reducing costly finishing operations. With EPS as your investment castings source, the only capital equipment investment required to produce the parts is the tool.

Cut Assembly Operations

Lost Wax process investment castings allow the replacement of multi-component parts with a single part. Several parts can be made as one casting, reducing handling, assembly and inspection costs.

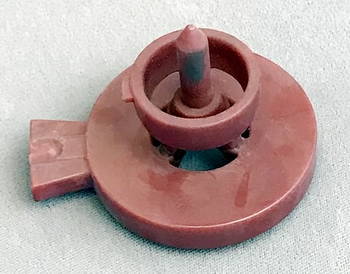

Reproduce Fine Details

The ability to reproduce fine details using the lost wax process allows EPS to produce a vast array of products from very close tolerance pressure fittings and valves to intricate trophies, medals and figurines.

EPS Has the Capability and Services You Need

Contact our experts at EPS with your needs. We will walk you through the process of getting the quality castings you need at a cost-saving price.

Fill out our short form and attach a drawing to receive a quote: